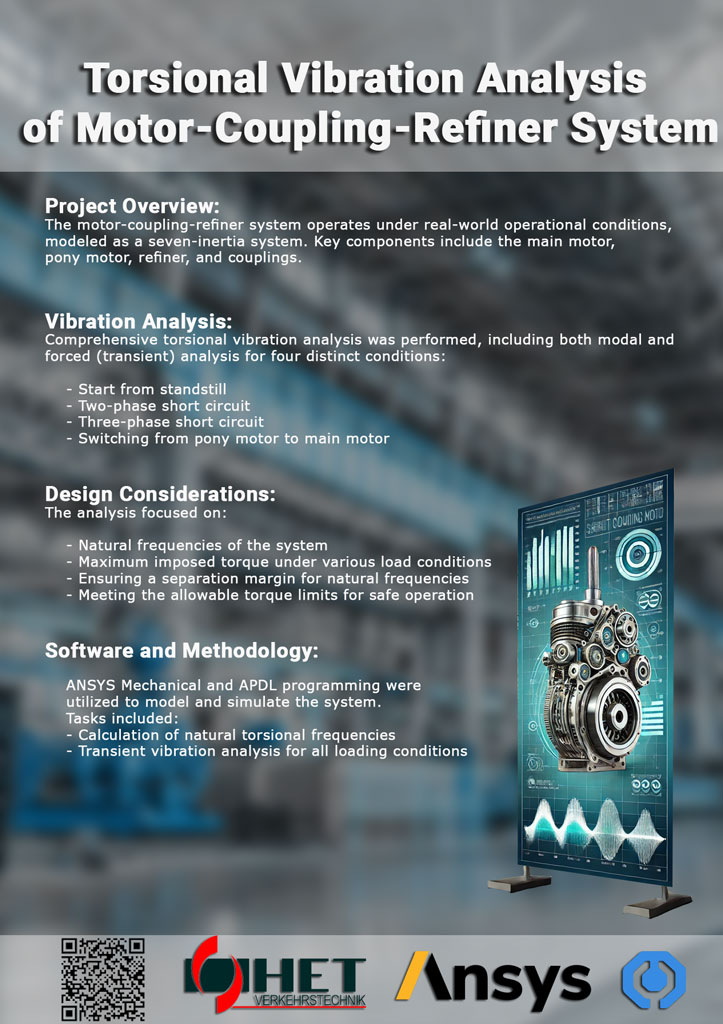

Torsional Vibration Analysis of Motor Coupling-Refiner System Project Description: This project focused on performing a detailed torsional vibration analysis for a motor-coupling-refiner system under operational conditions. The system, which plays a crucial role in pulp and paper refining processes, was modeled as a seven-inertia system, encompassing the main motor, pony motor, refiner, and couplings. The goal was to evaluate the system’s behavior under various operational scenarios and ensure it met critical design requirements. The analysis included both modal and forced (transient) vibration studies across four specific conditions: starting from standstill, two-phase short circuit, three-phase short circuit, and switching from the pony motor to the main motor. These scenarios represent typical and extreme operational conditions that the system may encounter, ensuring robustness and reliability under various stresses. Key objectives were to calculate the natural torsional frequencies of the system and assess the maximum imposed torque during different load conditions. This information was essential in verifying that the design included adequate separation margins for natural frequencies, preventing resonance, and ensuring that the torque limits were within safe operational thresholds. To carry out the analysis, ANSYS Mechanical was employed, with the model programmed using the APDL (ANSYS Parametric Design Language). The comprehensive simulation tasks included calculating both the natural frequencies and the forced transient vibrations for the four operating conditions. This approach allowed us to provide in-depth insights into the system’s dynamic behavior, ensuring optimal performance and durability in real-world applications. By addressing these critical factors, the project aimed to enhance the operational efficiency, safety, and reliability of the motor-coupling-refiner system, contributing to improved productivity in the pulp and paper industry.

⭐ M-File Scripts | MATLAB Tutorial ⭐

✍️ In this video, we have provided more detailed information about the difference of M-files scripts and functions. In this tutorial, we will try to explain the basics of MATLAB M-files scripts. M-files scripts are an efficient way of executing repeatedly commands with MATLAB. we will see their usage, how to make them (create, save, and run), and how to manage them. Also, we get familiar about ways that assignment of a value to a variable can be done.

⭐ M-File Functions | MATLAB Tutorial ⭐

✍️ Following MATLAB tutorials, in this tutorial, we will show the basics of MATLAB M-files functions. M-File functions are programs that accept input and return output arguments. We are going to find out the script side-effects and why should we use functions? Moreover, we get familiar with the syntaxes of M-File functions and the differences between functions and scripts.

⭐ Helical Gear Design | SolidWorks Tutorial ⭐

✍️ Helical gear design with SolidWorks is one of the topics that any engineer can be faced on a daily basis. It’s easy to do it inside SolidWorks. In this video tutorial we are going to learn how to draw helical gear in SolidWorks. we will get familiar with SolidWorks sweep feature and learn how to use tools like Revolve, Pattern, Extruded Cut, and Fillet in part design environment.

⭐ Defining Matrices | MATLAB tutorial ⭐

✍️ In this tutorial, we will learn how to create a matrix or vector in MATLAB. Matrices are fundamental to MATLAB. Therefore, we need to become familiar with matrix generation and manipulation. In this video, we are going to defining a matrix, extracting submatrices, transpose, and concatenation matrices. Also, we will see how to create larger matrices with predefined MATLAB functions (e.g. zeros, ones, eye, diag, rand), using generating linearly space vectors (linspace), and determining the size of matrices/vectors in MATLAB.