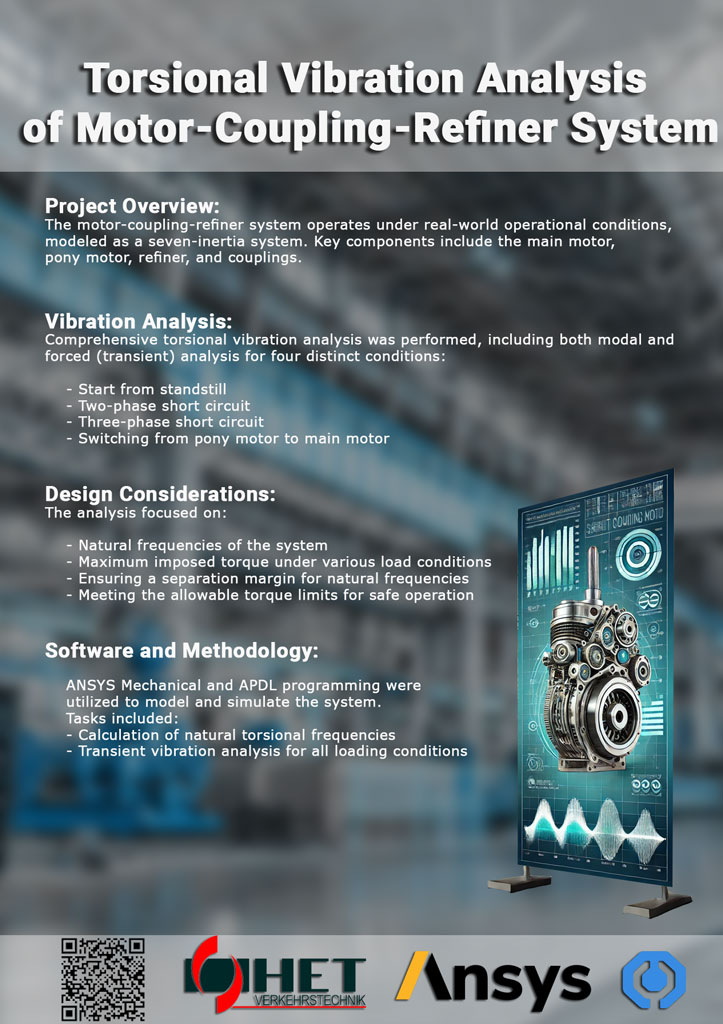

Torsional Vibration Analysis of Motor Coupling-Refiner System Project Description: This project focused on performing a detailed torsional vibration analysis for a motor-coupling-refiner system under operational conditions. The system, which plays a crucial role in pulp and paper refining processes, was modeled as a seven-inertia system, encompassing the main motor, pony motor, refiner, and couplings. The goal was to evaluate the system’s behavior under various operational scenarios and ensure it met critical design requirements. The analysis included both modal and forced (transient) vibration studies across four specific conditions: starting from standstill, two-phase short circuit, three-phase short circuit, and switching from the pony motor to the main motor. These scenarios represent typical and extreme operational conditions that the system may encounter, ensuring robustness and reliability under various stresses. Key objectives were to calculate the natural torsional frequencies of the system and assess the maximum imposed torque during different load conditions. This information was essential in verifying that the design included adequate separation margins for natural frequencies, preventing resonance, and ensuring that the torque limits were within safe operational thresholds. To carry out the analysis, ANSYS Mechanical was employed, with the model programmed using the APDL (ANSYS Parametric Design Language). The comprehensive simulation tasks included calculating both the natural frequencies and the forced transient vibrations for the four operating conditions. This approach allowed us to provide in-depth insights into the system’s dynamic behavior, ensuring optimal performance and durability in real-world applications. By addressing these critical factors, the project aimed to enhance the operational efficiency, safety, and reliability of the motor-coupling-refiner system, contributing to improved productivity in the pulp and paper industry.

ECS simulation conference – Linz

Magna ECS hosted a three-day conference in Linz from May 9th to May 11th, 2023, dedicated to the latest advancements in dynamic simulations and durability. Although I could only attend for half a day, I made sure to attend the Wednesday afternoon session. My colleague and I traveled from Herzograd to Voestahlstrasse in Linz, taking a train to the Ebelsberg station and then a city tram to the conference venue. The first presentation (by Dr. Christian Gaier, Magna Powertrain Engineering Center Steyr) I attended focused on the latest features of FEMFAT 2023, Magna’s specialized software for durability and fatigue analysis. With its advanced post-processing capabilities, FEMFAT uses FEM results from other softwares to calculate safety factors and remaining life of mechanical components. The software also incorporates FKM guidelines and other relevant methods for precise results, making it an invaluable tool for calculating the strength of weld seams and composite materials. The conference also featured discussions on the impressive achievements and potential applications of FEMFAT, as well as dynamic simulations. It was an enlightening experience to witness the latest developments in these fields and to be a part of this significant conference. One presentation that caught the attention of many attendees was by Dr. Gabriel Stadler from Montanuniversität Leoben, who discussed the Influence of creep load on the lifetime of short fiber reinforced polymers. As lightweight materials, short fiber reinforced polymers are becoming increasingly important in structural applications, particularly in the automotive sector. Another noteworthy presentation was by Per Nilsson from MAN Energy Solutions in Denmark, a ship engine manufacturer. His study focused on the FEMFAT Rotating Principle Stresses (RPS) Influence, a functionality that takes multiaxial effects into consideration. The study analyzed the influence of loading parameters such as phase, mean stress, and wave form and how they interact, with particular importance to the ship engine industry where the effect of multi axial stress is critical. The conference also coincided with Mr. Per Nilsson’s birthday, which was celebrated with a roomful of attendees singing “Happy Birthday” to him. Additionally, there were two FEMFAT workshops during the conference that allowed participants to see the software in practice, making the conference a valuable experience for all who attended. The ECS Simulation Conference was a great opportunity for experts in the field to come together and share their insights, leading to advancements and progress in the world of simulation. The day continued with a refreshing coffee break and then we delved into a presentation by Lukas Stenzel, a master’s student at KTM, about the method study for fatigue life evaluation of engine attachment points on the main frame of a motorcycle. His work highlighted a comparison of methods for the fatigue life evaluation of engine housings concerning the internal engine loads. Following that, Sven Maier from BMW presented a concept study on scattering input parameters in structural durability simulations applied to automotive components subjected to vibration loads. The presentation shed light on the numerous subsystems in modern vehicles that are mounted to the body-in-white structure for comfort, safety, digitalization, electrification, and autonomous driving functions. The study revealed that the vibration fatigue behavior of the subsystems and their connection to the body were significant factors, and the damping, mass, and thickness of the mounted component played a vital role in the vibration behavior of the system. Furthermore, the thicknesses of the plates had a substantial impact on the system’s natural frequencies, and a correlation between natural frequencies and calculated damage was derived. The ECS Simulation Conference was an exciting event for automotive engineers and simulation experts. The conference was held at the Linz Stahlhaus, and the presentations were informative and insightful. One of the standout talks was given by Markus Breitfuss, a colleague of mine from Magna Powertrain Engineering Center Steyr. His talk focused on the simulation-based fatigue assessment of car body structures. This topic is crucial for achieving the durability, lightweight, and cost targets in modern vehicle development processes. Markus explained the concept of inertia relief and dynamic contact analysis. These concepts are two essential processes used in simulation-based fatigue assessment. He also discussed how these processes complement each other and provide accurate and reliable results. The conference continues till next day with more talks and workshops but unfortunately I don’t have the chance to be there! You can also the check the ECS conference website for the full details of the presented Articles and more! However, todays talks were informative and thought-provoking, leaving the audience with new ideas and concepts to consider. As the presentations for the day concluded, I left the Linz Stahlhaus feeling inspired and excited about the future of simulation and automotive engineering. The ECS Simulation Conference was a great opportunity to learn from experts in the field.

Analysis of a pressure vessel for safety and earthquake loads

Analysis of a pressure vessel for safety and earthquake loads ✍️ In this project, we have optimized a pressure vessel to fulfil the requirements for earthquake safety as defined in EN 1998-1 ISO standard as well as in the pressure vessel codes. The FEM analysis results show that the original design needs to be optimized, the legs of the pressure vessel that are in contact with foundation plates do not provide enough strength to meet displacement criteria for earthquake accelerations. The optimized model presents a good solution for the weak parts of the original design and the pressure vessel can meet defined criteria based on EN 1998-1 and AD 2000 / EN 13445 with a good factor of safety.

FEM Analysis and optimization of middle class truck chassis

FEM Analysis and optimization of middle class truck chassis ✍️ In the critical parts of the front chassis of a middle class truck, we have determined the cause of the possible component failure and, proposed the optimized solutions using FEM.For this purpose, based on the geometric 3D model provided by customer and the defined load variants, we create an FE model in which the component-related behavior of the front chassis can be determined. This FE model is used to calibrate the design variations such as the front chassis geometry, strength and life time.

Hydrostatic Calculation | SolidWorks Tutorial

Comparison of FEM and analytical results for hydrostatic pressure calculation using SolidWorks simulation. One of the common issues in the engineering world is Hydrostatic pressure. Any plate exposed to a liquid, such as a gate valve in a dam, the wall of a liquid storage tank, or the hull of a ship at rest, is subjected to Hydrostatic pressure.

Woven Composites design | ANSYS Tutorial

✍️ In this tutorial we are going to learn about ANSYS Material Designer environment and its abilities. We will see how to design unidirectional and woven composites in ANSYS Material Designer and extract their homogenized material properties. Composite materials consist of two or more layered or otherwise integrated materials to create a new material with different material properties. These materials combine the best properties of their component materials, resulting in a product that is both light and strong.

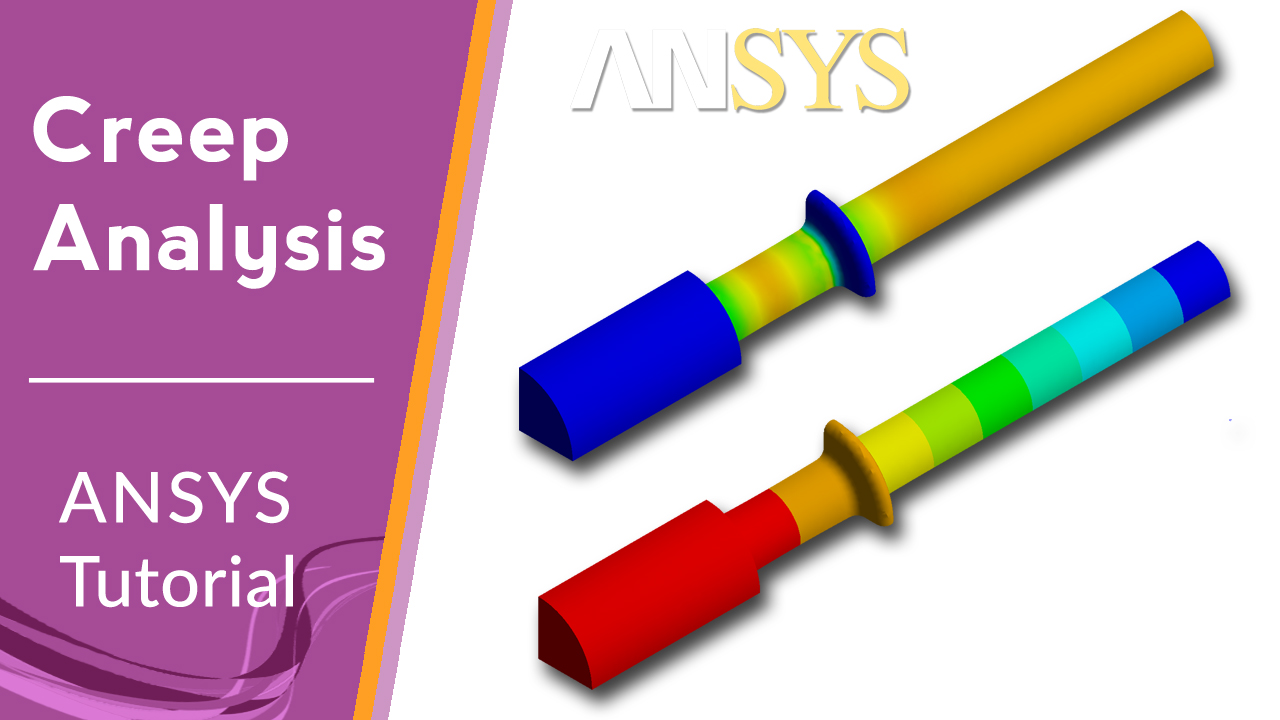

⭐ Creep Analysis | ANSYS Tutorial ⭐

✍️ In this tutorial, we are going to use ANSYS Workbench to simulate the creep deformation of an Aluminum Alloy (6061-T6) under constant stress and temperature. We will learn about the simulation of a Creep process in ANSYS Mechanical and analysis settings for Creep. For creep analysis, we will use Norton’s power law equation, which is the most important and widely used constitutive equation to predict the secondary Creep. We will see how to adjust the define material properties and settings of creep analysis in the static structural environment like creep effects, load steps, initial conditions, Creep Limit Ratio and Creep Strain Ratio.

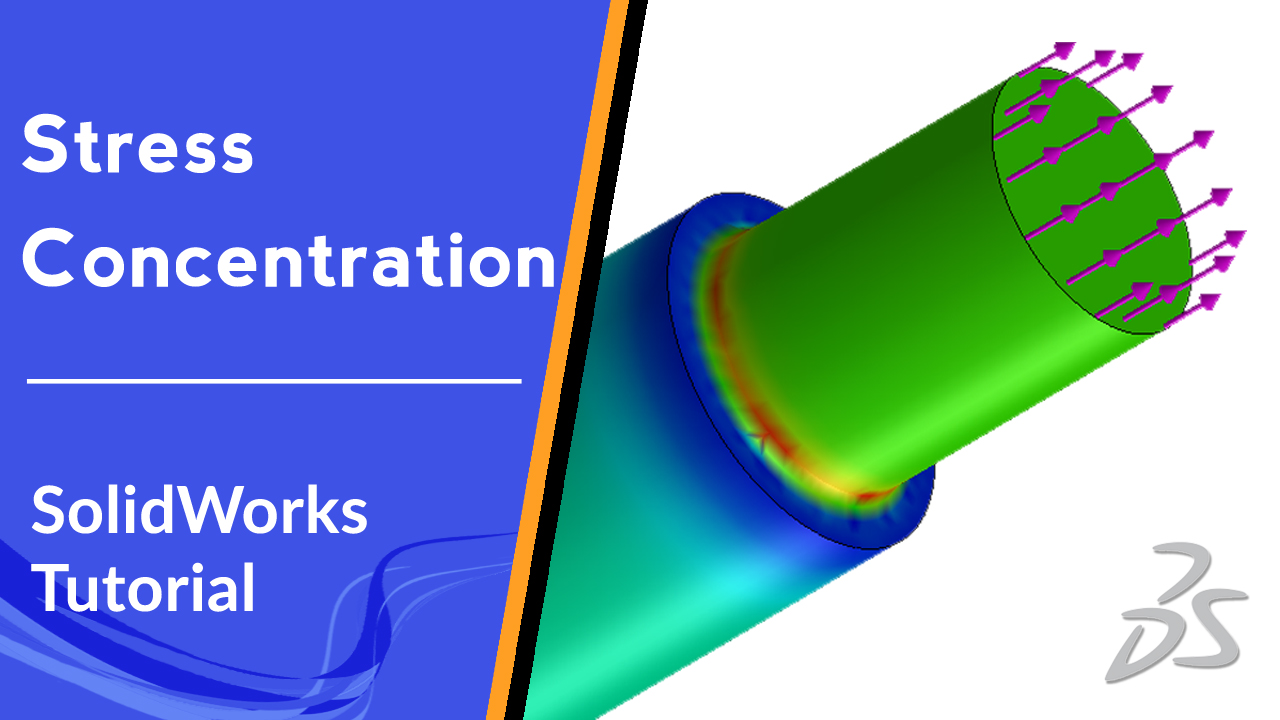

⭐ Stress Concentration Analysis | SolidWorks Tutorial ⭐

✍️ Following the SolidWorks tutorials, in this video, we will learn how to induce stress on a body in SolidWorks simulation. Also, we will see how to check stress concentration using both theoretical and finite element concepts and comparing results.