Analysis of a pressure vessel for safety and earthquake loads ✍️ In this project, we have optimized a pressure vessel to fulfil the requirements for earthquake safety as defined in EN 1998-1 ISO standard as well as in the pressure vessel codes. The FEM analysis results show that the original design needs to be optimized, the legs of the pressure vessel that are in contact with foundation plates do not provide enough strength to meet displacement criteria for earthquake accelerations. The optimized model presents a good solution for the weak parts of the original design and the pressure vessel can meet defined criteria based on EN 1998-1 and AD 2000 / EN 13445 with a good factor of safety.

FEM Analysis and optimization of middle class truck chassis

FEM Analysis and optimization of middle class truck chassis ✍️ In the critical parts of the front chassis of a middle class truck, we have determined the cause of the possible component failure and, proposed the optimized solutions using FEM.For this purpose, based on the geometric 3D model provided by customer and the defined load variants, we create an FE model in which the component-related behavior of the front chassis can be determined. This FE model is used to calibrate the design variations such as the front chassis geometry, strength and life time.

Simulation of the Impact Phenomena – ANSYS tutorial

✍️ In this tutorial, we will learn how to do a simulation of the Impact using ANSYS Explicit Dynamics. We use nonlinear materials for impact analysis. Through this tutorial, we will simulate the impact of a bullet on a steel wall. The dimensions of the model are chosen based on a calibre 22 bullet. We will find out about the steel wall resistance to the fired bullet, which hits it at a speed of 900 meters per second in a perpendicular direction.

Post Buckling Analysis of Cylindrical Shells – ANSYS Tutorial

In this video tutorial, we will learn about performing post buckling analysis of cylindrical shells under hydrostatic pressure in ANSYS Workbench. Also, we will see how to create pre buckled model of the cylindrical shell with the desired buckling mode and deformation scale factor for use in the post-buckling analysis. Cylindrical shells can fail due to compression in the longitudinal or circumferential direction, or due to shear. But usually, due to all of those effects combined in one way or another. Plus, this can happen locally or globally.

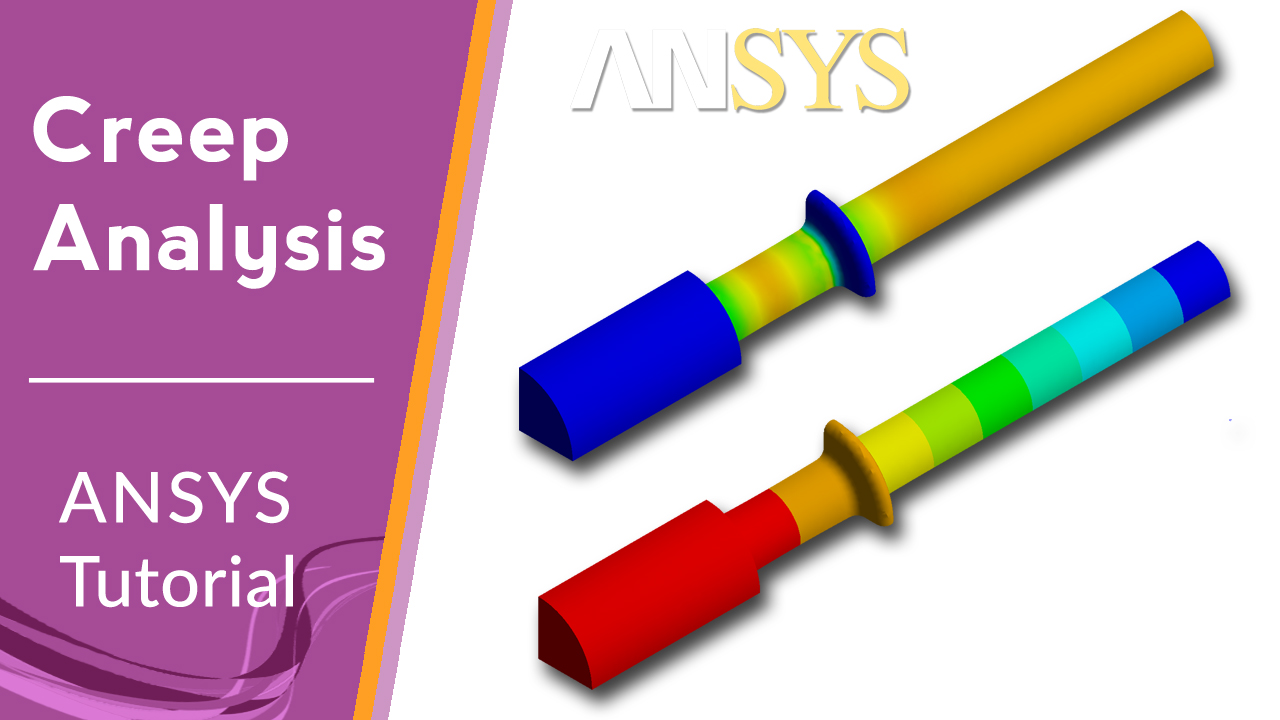

⭐ Creep Analysis | ANSYS Tutorial ⭐

✍️ In this tutorial, we are going to use ANSYS Workbench to simulate the creep deformation of an Aluminum Alloy (6061-T6) under constant stress and temperature. We will learn about the simulation of a Creep process in ANSYS Mechanical and analysis settings for Creep. For creep analysis, we will use Norton’s power law equation, which is the most important and widely used constitutive equation to predict the secondary Creep. We will see how to adjust the define material properties and settings of creep analysis in the static structural environment like creep effects, load steps, initial conditions, Creep Limit Ratio and Creep Strain Ratio.

⭐ THERMO-MECHANICAL ANALYSIS OF DIFFUSER SUPPORTING LEGS

In this project we have investigated the stress distribution in a system of diffuser support legs which was used in the Annealing unit of a galvanized steel company. Some of the supporting legs failed duo to high temperature and loadings and we have analyzed several scenarios for optimizing the design of these supporting legs.