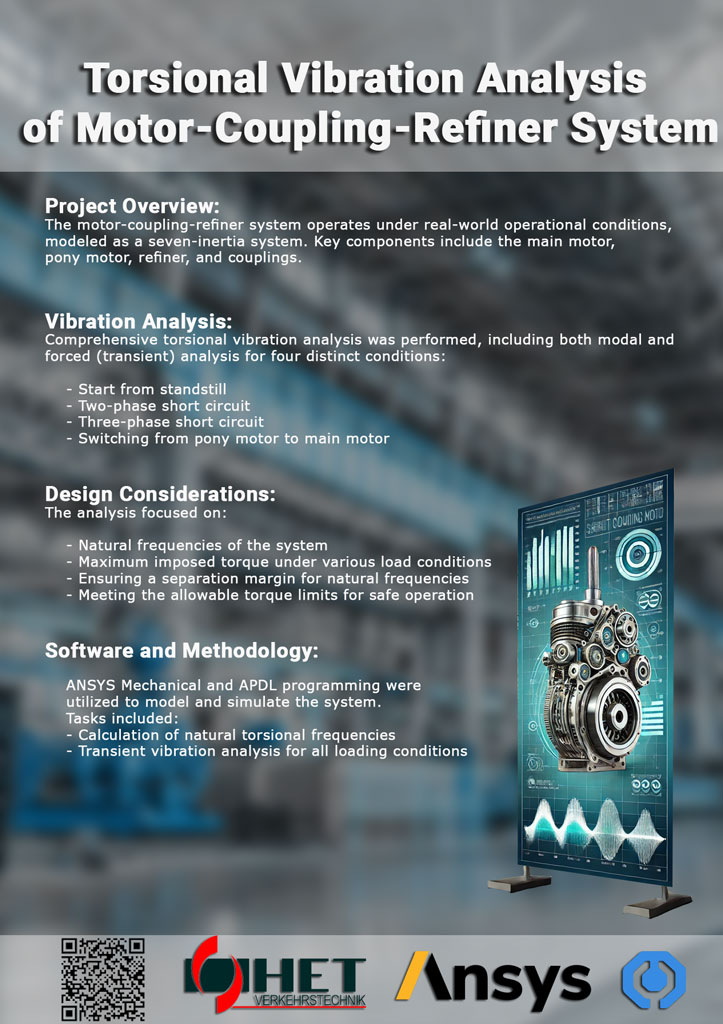

Torsional Vibration Analysis of Motor Coupling-Refiner System Project Description: This project focused on performing a detailed torsional vibration analysis for a motor-coupling-refiner system under operational conditions. The system, which plays a crucial role in pulp and paper refining processes, was modeled as a seven-inertia system, encompassing the main motor, pony motor, refiner, and couplings. The goal was to evaluate the system’s behavior under various operational scenarios and ensure it met critical design requirements. The analysis included both modal and forced (transient) vibration studies across four specific conditions: starting from standstill, two-phase short circuit, three-phase short circuit, and switching from the pony motor to the main motor. These scenarios represent typical and extreme operational conditions that the system may encounter, ensuring robustness and reliability under various stresses. Key objectives were to calculate the natural torsional frequencies of the system and assess the maximum imposed torque during different load conditions. This information was essential in verifying that the design included adequate separation margins for natural frequencies, preventing resonance, and ensuring that the torque limits were within safe operational thresholds. To carry out the analysis, ANSYS Mechanical was employed, with the model programmed using the APDL (ANSYS Parametric Design Language). The comprehensive simulation tasks included calculating both the natural frequencies and the forced transient vibrations for the four operating conditions. This approach allowed us to provide in-depth insights into the system’s dynamic behavior, ensuring optimal performance and durability in real-world applications. By addressing these critical factors, the project aimed to enhance the operational efficiency, safety, and reliability of the motor-coupling-refiner system, contributing to improved productivity in the pulp and paper industry.

Analysis of a pressure vessel for safety and earthquake loads

Analysis of a pressure vessel for safety and earthquake loads ✍️ In this project, we have optimized a pressure vessel to fulfil the requirements for earthquake safety as defined in EN 1998-1 ISO standard as well as in the pressure vessel codes. The FEM analysis results show that the original design needs to be optimized, the legs of the pressure vessel that are in contact with foundation plates do not provide enough strength to meet displacement criteria for earthquake accelerations. The optimized model presents a good solution for the weak parts of the original design and the pressure vessel can meet defined criteria based on EN 1998-1 and AD 2000 / EN 13445 with a good factor of safety.

FEM Analysis and optimization of middle class truck chassis

FEM Analysis and optimization of middle class truck chassis ✍️ In the critical parts of the front chassis of a middle class truck, we have determined the cause of the possible component failure and, proposed the optimized solutions using FEM.For this purpose, based on the geometric 3D model provided by customer and the defined load variants, we create an FE model in which the component-related behavior of the front chassis can be determined. This FE model is used to calibrate the design variations such as the front chassis geometry, strength and life time.

Simulation of the Impact Phenomena – ANSYS tutorial

✍️ In this tutorial, we will learn how to do a simulation of the Impact using ANSYS Explicit Dynamics. We use nonlinear materials for impact analysis. Through this tutorial, we will simulate the impact of a bullet on a steel wall. The dimensions of the model are chosen based on a calibre 22 bullet. We will find out about the steel wall resistance to the fired bullet, which hits it at a speed of 900 meters per second in a perpendicular direction.

Post Buckling Analysis of Cylindrical Shells – ANSYS Tutorial

In this video tutorial, we will learn about performing post buckling analysis of cylindrical shells under hydrostatic pressure in ANSYS Workbench. Also, we will see how to create pre buckled model of the cylindrical shell with the desired buckling mode and deformation scale factor for use in the post-buckling analysis. Cylindrical shells can fail due to compression in the longitudinal or circumferential direction, or due to shear. But usually, due to all of those effects combined in one way or another. Plus, this can happen locally or globally.

Step by step Transient Thermal Analysis – Cooling of molten Aluminum

Transient thermal analysis is an important procedure to determine the thermal behavior of a system in a specific period of time. In phase transition of molding process or in electronic parts simulations it is essential to consider the timely behavior of temperature changes. Using ANSYS transient thermal module we can evaluate complex systems in a fast and efficient way. In this video tutorial, the molten aluminum is entered into the mold at 800°C while the temperature of the mold is initially at 30°C.

Multi-Objective Optimization of Composites using ACP & Mechanical

In this tutorial, the step by step procedure of multi-objective optimization of composites by ANSYS composite PrepPost (ACP) and the mechanical module is described. Finding the best method for arranging the thickness and angle of composite layers is always very challenging and can be time-consuming. With the help of ANSYS composite PrepPost, optimization methods, and an ANSYS specialist, this procedure can be done much easier and faster than experimental methods.

Design of a composite joint in Ansys Composite PrepPost (ACP)

In this video tutorial, we are going to model a composite joint using Ansys Composite PrepPost with full details. It demonstrates an assembly modeling approach in ACP and highlights the strengths of the oriented element sets. T-Joints are typical connections in composite constructions. They are used to connect two parts at right angles.

Design in engineering

✍️ Design in engineering is a key topic. Have you ever thought about how to design a new product and develop an existing device or system? With creative design steps, you will find the solution and getting familiar with the design path. You want to design or invent a new device? Then give a hand to your design process by following these essential design steps. Design like an engineer to find a structural way for your variant phases of design.

Hydrostatic Calculation | SolidWorks Tutorial

Comparison of FEM and analytical results for hydrostatic pressure calculation using SolidWorks simulation. One of the common issues in the engineering world is Hydrostatic pressure. Any plate exposed to a liquid, such as a gate valve in a dam, the wall of a liquid storage tank, or the hull of a ship at rest, is subjected to Hydrostatic pressure.